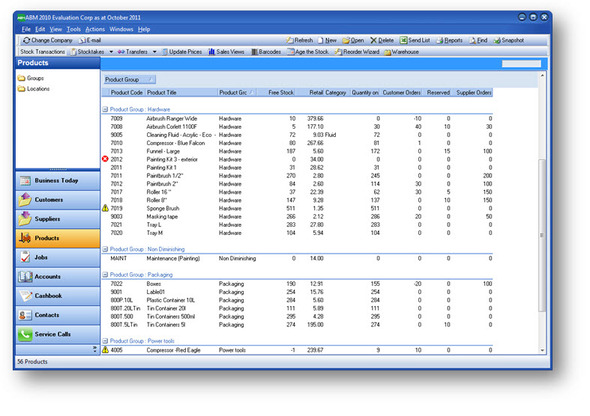

Inventory & Stock Control

ABM’s Stock Control facility can increase your product handling efficiency and ease. ABM manages multi stock locations, serial and lot number tracking, products made up of individual components and more...

Stocktake

The stock take procedure in ABM is broken down into stock organisation and stock entry, allowing for minimal system downtime during the process.

Optional warehouse module

ABM's Warehousing module provides logical control and organisation of stock, allowing users to create a hierarchal structure in each warehouse with multiple aisles, levels and alike. and a waiting area for goods not yet put away. The module uses "bins" to organise and group stock depending on the user's grouping method, location, level or stage.

Set unique prices

Store a virtually unlimited number of special prices for customer groups or specific customers, in each product with the option to start and end the special prices on selected dates.

Import supplier price lists

For fast easy ordering of stock, import supplier price lists for 'point and click' ordering of new stock.

View stock movement

Graphs permit the fast interpretation of key information, with stock status automatically updating through stock transactions.

E-mail product sales information

One click e-mailing of promotional sales information, product pictures and links to related websites.

Produce reports

Reports show an up to date picture of the sales and gross profit for a selection of product lines.

Product Kits & Components

Assign components to a product. Pick a product and display the components, view the sale and cost price of the components and the sale price of the kit product.

|

View product kits demonstration video |

Serial number or batch lot tracking

ABM allows you to enter the serial number of a product at the point of purchase and to track it thereafter. Tracking also includes product ‘use-by-dates’.

Automatic price list update

Change prices quickly and easily. Select a product group and increase or decrease the prices by a percentage or amount.

ABM also supports...

|

non-diminishing stock multi-location with minimums and bin numbers per location weighted average, FIFO or standard costing maximum and minimum quantity levels |

re-order and lead times stock ageing analysis visual warning of stock shortages supplier rebates |